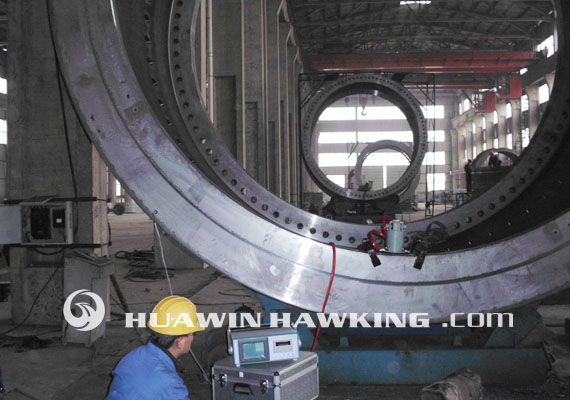

VSR technology, foreign called "Vibrating Stress Relief" (referred to as VSR), designed by a dedicated VSR equipment, so that the workpiece is processed resonance, and in this way a certain resonance energy transfer to the vibration of the workpiece All parts of the workpiece within the micro-plastic deformation occurred - the gradual recovery of the lattice is distorted equilibrium. Dislocation slip and re-pinning, and thus the residual stress within the workpiece can be overcome and are, eventually, to prevent the workpiece in the processing and use of deformation and cracking, to ensure the stability of the workpiece dimensional accuracy.

In recent years, VSR to less investment, effective, efficient, energy saving, environmental protection and other advantages, unstoppable, has been gradually replaced by heat aging.

VSR heat aging compared with conventional technology, has the following advantages:

1 VSR less investment

Compared with the thermal aging, aging VSR without huge furnace can save floor space and expensive equipment investment;

Thermal aging, less if the workpiece is not worthy of the open furnace, Shi does not fit the workpiece is too large heaters. And furnace temperature uniformity is difficult to eliminate the stress effect

Difference. VSR is used to avoid these problems.

2 VSR aging effect

A lot of research and practical applications show that the limitation of the workpiece VSR better than burning coal, heavy oil or gas heat aging furnace, and basic and electricity

Similar effect of aging furnace, because VSR not only overcome the uneven heat aging furnace to eliminate the stress caused by uneven the problem, and avoid

Workpiece due to heat and reduce the impact of its resistance to deformation, it is generally handled by the VSR parts than the average thermal aging of the size of the workpiece

Stability can be increased by 30% or more.

3 VSR flexibility

VSR from the use of space technology, workpiece size, shape, weight and other conditions, because only a few dozen kilograms of VSR equipment,

Therefore, a large piece of land may be aging. At the same time can be arranged according to process requirements of different manufacturing processes in the workpiece between the aging process.

4 VSR solve the thermal aging furnace problem of environmental pollution

With the increasing demand on the environment, heat aging furnace flue gas, dust, slag, the problem has been restricted, VSR is completely avoided,

This is also the country has been VSR technology is to promote the cause.

5 VSR significant energy saving

VSR processing cycle down a few degrees only electricity, heat aging compared with its base in more than 95% energy saving.

6 VSR efficiency

Subject to natural aging six months to one year, more than a dozen thermal aging also needs to dozens of hours of a cycle, and only ten minutes to VSR

One hour to complete.

7 VSR not particularly suitable for high-temperature aging of materials and components to eliminate the stress treatment.

Such as stainless steel parts, non-ferrous metal parts, mechanical parts after repair welding, etc.

|